5 Steps for More Successful Plant Phenotyping Platforms

Over the last 7 years, I have worked in two major phenotyping companies and have overseen the design, construction and installation of more than 15 large-scale plant phenotyping platforms worldwide. With this background I have gained an interesting view into the development processes and different approaches people took. In the past, phenotyping has been an emerging market with only a few players. The lack of alternatives in such a young oligopolistic market has resulted in bad product quality and wrong product constellation for the given application. This has applied to both self-build- and commercial-systems. In addition to that, miscommunication and a lack of experience has led to wrong expectations of scientists and suppliers. With the increasing amount of companies offering phenotyping equipment and the experience gained over the last years, it is time for the next generation of plant phenotyping platforms.

Personally, I am fascinated by the challenge to automate complex processes like the assessment of plants in high throughput in close collaboration with biologists, engineers and computer scientists to develop the best possible solution. It is, of course, always a hard journey to fit all wishes, ideas and features into the given budget and a lot of times we need to compromise or modify plans. However, we never lose the objective: to build a tool that solves a problem and answers a biological question.

With this background I want to point out 5 steps that can help suppliers and scientists to design more satisfying plant phenotyping platforms.

The Problem

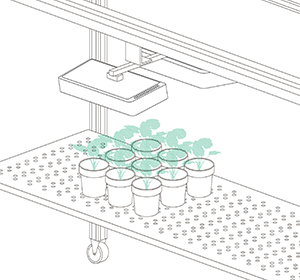

The question, ‘Why do you want to build an automated phenotyping platform?’ should be answered first. Sometimes it seems that people are looking for some arbitrary tech-toys rather than focussing on the underlying problem. When you start to think about automated plant phenotyping platforms, you most likely have a problem in mind that you need to solve. Maybe your current phenotyping approaches are very labour intensive and you want to increase throughput, accuracy, resolution or reduce labour costs. Whatever it was that brought you to this point, make sure to define the problem and set yourself a clear and measurable target, otherwise you will end up with a nice machine that delivers gigabytes of irrelevant data.

The Concept

When you know the problem, be creative and think of how to approach it. The sky’s the limit! (In most cases the budget probably is the sky!) Instead of focussing on existing technologies within the industry, find your own concept by looking at what other people have done so far and try do to your own mistakes rather than repeating theirs. Whenever a supplier is included in such a process, the concept might become biased. Are they helping to improve your concept or are they trying to slip their product specifications into your concept? Let the question drive your concept and not the technology.

One other aspect is the required flexibility. In my experience, discussions start with a clear and simple concept. When this concept is almost finalized, people often become too creative and add more and more wishes of what this platform should do. I don’t believe there is any system that can measure everything, so be sure to keep your concept realistic and focused to the problem. If one system can’t do it all, consider splitting it up into smaller packages and if somebody tells you his concept can do everything, be cautious.

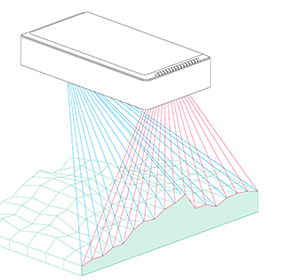

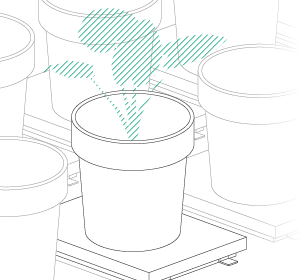

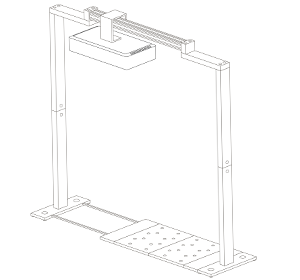

The Technology

In this step, the input of somebody who technically realizes your concept is needed. You have already formulated an interesting problem and designed a good concept, but now you need to align your ideas with another party without losing focus. When you start discussion with suppliers, ask them directly for the benefits of their technology for your concept. Some suppliers try to impress with technical features. ‘The new Pheno-Gizmo, now with a 32 MP camera!’ A 32MP camera is a nice feature, but is there any benefit from it compared to a much cheaper 12MP camera? Simplicity is the ultimate sophistication. The more complex the system, the more sources of error you will have.

Another important aspect of finding matching technology is the available budget. On the one hand, as a supplier I need to get a feeling for how much financial leeway there is to play with. On the other hand, you can be almost certain that the supplier will quote close to the budget limit if he knows how much money is available. My recommendation is to get a written price indication early in the project phase without revealing the exact budget. When you apply for funding, make sure it includes all needed parts. In a later phase ask for a precise quotation and indicate the approved budget. Of course, it is worth contacting different suppliers to compare value for money.

The Validation

The field of phenotyping is still too young to have any ‘turnkey’ solutions. When you choose a technology that seems suitable, evaluate it. The maxim should be: Test before invest. Without a small-scale validation, up-scaling is very risky. My personal advice is that a validation should be more than a fancy sales pitch or a quick look and feel. Ask for some references and speak with them (favourably without the supplier). After that speak to the references the supplier didn’t give you. If possible, rent the equipment or at least ask for a test experiment. If no technology seems feasible, reconsider your concept.

The Product

If the previous steps have been carried out with reasonable care and the best technology was chosen, the implementation of the product is a matter of good project management from you and the supplier. Don’t stand on the side-lines and watch, get involved. Request status updates every week, set important milestones and try to get direct access to the project planning. I just implemented an online project management tool here at Phenospex that allows our customers direct access into the project planning. They can login and get the recent status of their project whenever they want. This way you can launch countermeasures in case of problems or delays. Having a transparent implementation process provides a feeling of security when investing large amounts of money.

After a successful setup, don’t expect to go into productive research mode straight away. It is probably at least the first 2 experiments on such a phenotyping platform will either go wrong because of technical- or application-errors. Plan some time for improvement with the supplier; schedule a follow up visit a couple of months after commissioning to work on open points. In this phase the supplier really needs to show that he cares about his customers and that he keeps his promises. Setting up a platform is one thing, but making you completely satisfied is the real challenge.

At the end you will have a system that is well designed and matches your expectations. The ultimate goal of phenotyping is to generate knowledge from your system and to solve the scientific questions. As a supplier I will benefit from working with you on that solution to make phenotyping a bigger success, resulting in better products and more useful tools. Although answering the first question will raise another ten, to be honest, I think this is the fun part in developing the plant phenotyping market.